CYCLO® Gearmotor with Torque Limiter

Detect overloads instantaneously with installed torque limiter

- Cyclo gearmotor with installed torque limiter to detect overloads

- Protects your valuable machines from catastrophic failure.

- The torque limiting is applied at the drive part, allowing you a more accurate examination of your device safety factor, which makes optimal equipment design possible.

| Output Shaft | Solid Shaft |

| Output Shaft Direction | Horizontal, Vertical Downward, Vertical Upward, Univversal |

| Mounting Method | Foot Mount, Flange Mount, Case Mount |

| Number of Sizes | 15 sizes |

| Reduction Ratio | 6 - 658503 |

| Motor Capacity | 0.2 kW - 30 kW |

| Motor Types | Three Phase, Premium Efficiency, High Efficiency, For Inverter, Outdoor, Increased Safety Explosion Proof, Flameproof, Overseas Standard |

Key Product Facts

±10

%

accuracy of configured torque ±5 - ±10%

±25

%

Adjustable range for the configured torque

0

Worry

Our Cyclo Gearmotor provides safe, worry-free performance with built-in safety features.

Features

Compact

Compact Cyclo reducer boasts a high reduction ratio, high efficiency, and a small number of parts, including a superior built-in torque sensor (spring / limit switch type, load cell type).

High Accuracy and Reliability

The sensor base consists of coiled springs or load cells, and features high accuracy and reliability. (Accuracy of configured torque ±5 - ±10%)

Allows for Economical Equipment Design

The torque limiting is applied at the drive part, allowing you a more accurate examination of your device safety factor, which makes optimal equipment design possible.

Operates During Momentary Overload

The mechanical torque detection mechanism allows for a shorter detection time compared to thermal relays, detecting overloads instantaneously.

Wide Range of Torque Adjustment

The adjustment range for configuring the torque is a wide ±25%, which means adjustments can easily be made on-site to match the actual torque of the equipment. (However, it must be within the maximum and the minimum configured torque).

Safe Unattended Operation

Built-in buzzer and indicator light in the motor operation circuit ensures a safe unattended operation. By using either the double or triple safety models, it is also possible to drive the auxiliary motor for a thickener shaft.

Combine with Other Protection Equipment

Can be combined with shear pins to achieve double or triple protection against overloads.

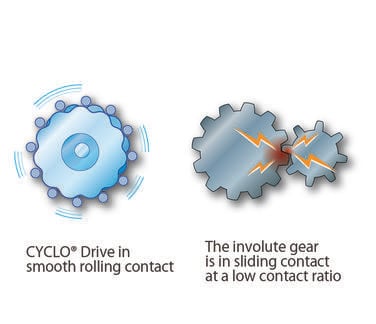

Break-resistant Teeth

Unlike a regular involute tooth-gear, the "cycloidal disc," which is the gear for the Cyclo Reducer, features a distinctively smooth curve.

A unique circular-arc tooth profile is also used for the internal gear. The smooth rolling contact that prevents tooth breakage results in a durable reducer with a long service life. (Some low reduction ratio models use helical gears and planetary gears.)