CYCLO Drive

Our best-selling gearmotor with high strength and reliability, thanks to its unique CYCLO® mechanism.

- With its long history and delivery record, it has become synonymous with the term speed reducer.

- Unique Cyclo mechanism results in high durability and extended operating life.

- Wide variety of products available that take advantage of this technology.

- Select the best product to meet your needs from a wide range of capacities and reduction ratios.

*CYCLO is a registered trademark of Sumitomo Heavy Industries, Ltd.

| Output Shaft | Solid Shaft |

| Output Shaft Direction | Horizontal, Vertical Downward, Vertical Upward, Universal |

| Mounting Method | Foot Mount, Flange Mount, Case Mount |

| Frame Size | 56 sizes (Output stages) |

| Reduction Ratio | 2.5 - 658503 |

| Motor Capacity | 0.1 kW - 132 kW |

| Motor Types | Three Phase, Premium Efficiency, High Efficiency, For Inverter, Outdoor, Increased Safety Explosion Proof, Flameproof, Overseas Standards, High Speed Hollow Shaft |

Mechanism

By adopting unique cycloidal (trochoidal) gear mechanism, excellent impact resistance and high efficiency are achieved.

Furthermore, a wide range of reduction ratios from 6 to 119 can be produced with a single stage of reduction, allowing for the compact consolidation of the gear components.

Features

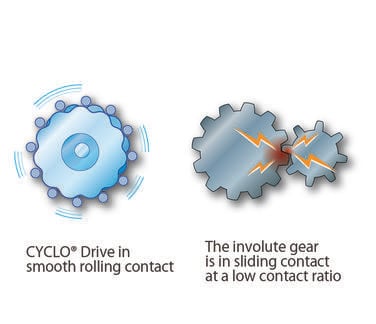

Unbreakable gear tooth profile

“Cycloid disc”, the gear of the CYCLO Drive, has a unique smooth curvature (epitrochoid parallel curve) which is different from the curvature of the typical involute gear. In addition, the unique circular tooth profile has also been adopted for the internal gear. Smooth rolling contact with no breakage of the tooth has achieved a tough and long life reducer.

(Some of the reducers with the specifications of a low reduction ratio have adopted the helical gear or the planetary gear.)

Various Applied Products

Various applied products are available.

The most suitable one according to the applications can be selected.

Abundant variations

Abundant variations with capacity of 0.1 kW to 132kW and reduction ratio of 2.5 to 658503 are in the lineup.

Use of SF (Service Factor)

SF for CYCLO Drive can be freely selected unlike SF for the typical gearmotor.

Only the frame size of the reducer can be sized up without increasing the motor capacity range.

Registered Trademarks

The academic and general term for "Cycloidal Gear Reducer" is "Planetary Gear Reducer with Trochoidal Profile," and the names "Cyclo®" and "Cyclo Gear Reducer®" are registered trademarks that can only be used for products manufactured and sold by our company.