E CYCLO® High Precision Gearboxes ECY Series

Strain Wave Gear System × CYCLO Drive Gear

ECY series integrates the strain wave gear with the the engagement theory or the CYCLO Drives, thus realizing unprededented high rigidity and a compact structure.

- The structure differs from a general strain wave gear, realizing high strength.

- Ideal for robotic and machine tool applications.

- Easy to mount the shaft on the device or on the motor.

- The space of hollow shaft diameter can be used effectivelly.

| Lost Motion | 1.0 acrmin |

| Allowable Peak Torque | 44 - 157 N•m |

| Reduction Ratio | 50 - 100 |

Key Customer Benefits

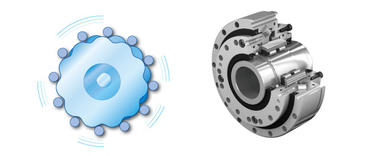

CYCLO® Drives were created and developed by Sumitomo. This unique reducer structure without teeth (trochoid tooth profle*) is being used in industrial robots and transfer devices all over the world. The ECY Series, which was developed as a compact non-backlash reducer,

integrates the strain wave gear with the engagement theory of the CYCLO Drives, thus realizing unprecedented high rigidity and a compact structure.

* Epitrochoid parallel curves

Point1

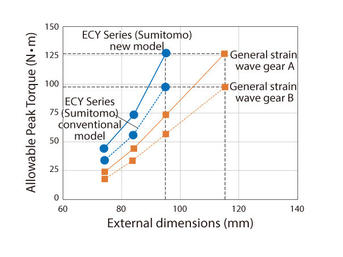

Compact and High Torque

The allowable peak torque increased 30% from the conventional model. New model has high torque compared to general wave gear, contributing to make the device more compact.

Point2

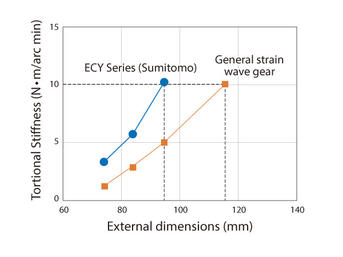

High Rigidity

The tortional stiness is approximately twice (representative value) as large as that of the general strain wave gear (equivalent size).

Thus it can increase the device's strength and reduce vibration, etc.

Point3

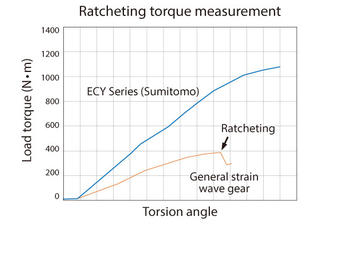

Ratcheting Resistence (Safety under Overload)

The structure suppressing ratcheting (situation where teeth do not engage smoothly) realizes high safety under overload.

Point4

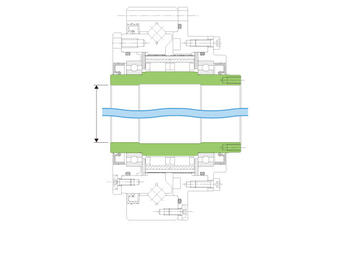

Large Diameter of High Speed Hollow Shaft

The diameter of high speed hollow shaft is large, which enables efective use of its space; for passing the cable, as the space for the shaft, and etc.

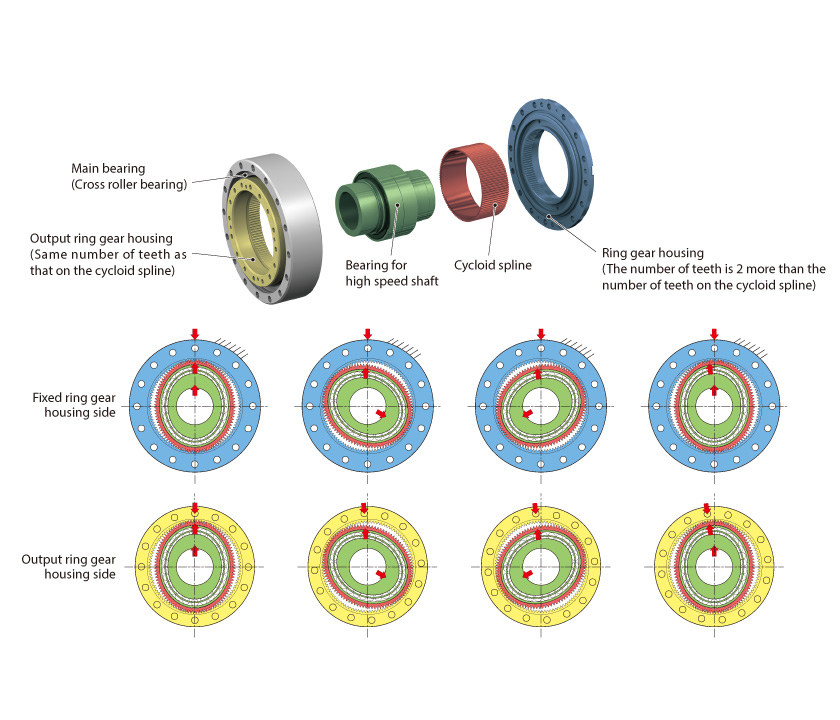

Operating Principle

As a principle rule, the ECY Series consists of 4 parts.

- The bearing for eccentric deforms the cycloid spline into an elliptical shape.

- The major axis of the cycloid spline that was deformed into an elliptical shape engages the fxed ring gear housing and the output ring gear housing.

- When the fxed ring gear housing is fxed and the bearing used for the eccentric body is turned 1 rotation in the clockwise direction, the cycloid spline will rotate in the counterclockwise direction by an amount corresponding exactly to the di erence in the number of teeth, while the elastic deformation is changing.

- This amount of rotation is taken on at the output ring gear housing.

Application Example

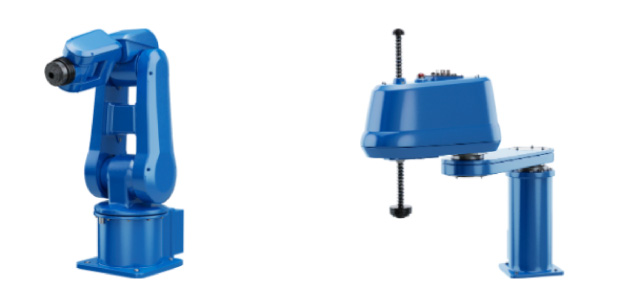

1. Small Robot

- Vertically articulated robot, Selective compliance assembly robot arm,

- Collaborative robot

2. Small Manipulator

- Joint drive

3. Processor

- Main shaft drive, Table drive

4. Semiconductor Producing Equipment

- CPM device

5. Taking robot